Wood is used in both internal and exterior design since the beginning. The way that wood was used evolved with civilization. Thanks to developments in manufacturing, wood is becoming more and more useful for utilities. With time, woodworking gained popularity as a talent.

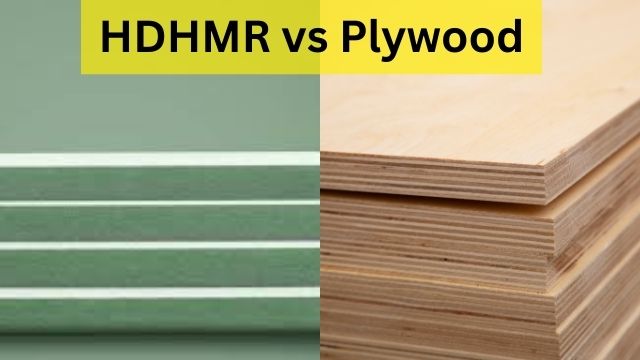

Two materials commonly used in the construction of furniture, cabinets, and other fittings are HDHMR and plywood. Potential buyers and builders can make a thorough decision by weighing the benefits and drawbacks of the two. Let us begin this fascinating and instructive debate about HDHMR vs plywood now.

What is HDHMR (High-Density High Moisture Resistance) Board?

HDHMR combines fiber scraps and residual forest wood in a homogeneous manufacturing process. A more dense, robust board is produced by removing a portion of the wood and crushing these fiber pieces into a single layer. The product has an improved density compared to other things available.

HDHMR is transforming the Indian interiors market by dispensing with plywood thanks to its unmatched quality and endless applications.

Its remarkable resistance to moisture makes it a popular choice in areas with severe weather. Because these boards can withstand termite and borer infestations, they are a superior choice to plywood. Due to special German MAT forming technology, these boards have a compact core and a continuous density gradient. Producing the best routing characteristics and a wide range of thicknesses in many diameters, from 1.9 mm to 45 mm.

What is Plywood?

The engineered wood, known as plywood or plyboard, is made by gluing together thin wood layers, which are usually bonded together using a resin under high pressure. The quality of the plies is determined by the wood chosen. Plywood is a combination of hardwoods and softwoods. Furthermore, plywood is less costly than HDHMR.

The origin or source of the wood greatly influences the quality of plywood. Both home and commercial environments employ plywood. Plywood can be cleaned using a dry cloth, but it must be kept out of the light and moisture.

Parameters comparison

Source

- Wood veneer is the source of plywood.

- Fiber chips and leftover forest wood are the sources of HDHMR.

Structure

- Plywood is low-density and non-uniform.

- The surface of HDHMR is uniformly high-density.

Durability

- HDHMR is more durable than plywood.

- Plywood is less durable than HDHMR.

Infestations

- Termites are more likely to infest plywood.

- Termite infestations are less likely to affect HDHMR.

Resistance to Water

- Water does not pass through plywood.

- HDHMR provides excellent water resistance.

Main Differences Between Plywood and HDHMR

- Compared to HDHMR, plywood is subject to increased wear and strain.

- Compared to HDHMR, plywood is a less popular option among homemakers and interior designers.

- Some well-known plywood brands are Duro and Greenply. Conversely, Action Tesa is the most well-known HDHMR brand.

- While HDHMR gives a clean surface, greater density, and consistency, plywood requires more upkeep.

- One of plywood’s drawbacks is that it could be more homogeneous and dense. However, the increased weight of HDHMR relative to other building materials is a drawback.

Strength and Durability

In terms of durability and strength, both HDHMR and plywood have benefits.

HDHMR: HDHMR is an excellent material for heavy-duty fixtures and furniture because of its high density, which enables it to support a substantial weight. Because of its great moisture resistance, which prevents swelling along with other water damage, it additionally has a longer lifespan.

Plywood: Because of the layering technique used in its creation, plywood is well known for its structural strength. Its multi-layered structure prevents warping and maintains its shape for a long time by offering well-balanced stability.

Working with the Materials

Materials which are long-lasting and easy to work with are essential for craftsmanship. Let’s examine the results in this region for plywood and HDHMR.

HDHMR: Due to its density, cutting and shaping HDHMR requires specialized tools. Once mastered, however, it offers a smooth surface ideal for laminations and veneers, along with a polished finish.

Plywood: This material is simple to mold, install, and work with. It is also quite flexible. Its mild bending flexibility allows it to be used for a wide range of applications, including curved surfaces, which is challenging to achieve with other materials.

Environmental Impact

In this era of environmental concern, it is critical to understand the ecological footprint of the commodities we use.

HDHMR: By utilizing wood fibers, which are typically derived from wood waste, HDHMR is claimed to be environmentally friendly as it promotes recycling and reduces the demand for new timber supplies. Furthermore, waste is minimized throughout the production of HDHMR.

Plywood: Nonetheless, dangerous adhesives that release volatile organic compounds (VOCs) into the air may occasionally be used throughout the plywood-making process. However, efforts are underway to reduce the environmental impact of plywood by manufacturing the material with more environmentally friendly adhesives.

Visual Flexibility

In terms of aesthetics, each material has specific benefits.

HDHMR: For various finishes, including laminates and veneers, HDHMR offers a uniform, smooth surface. Because of its consistency, interior designers can develop a cohesive style.

Plywood: With various finishes, the natural wood grain appearance of plywood can be brought to life, and its inherent beauty is highlighted. Its ability to be shaped into curved surfaces gives designers even more freedom to be imaginative and innovative.

Cost-Effectiveness

Cost is a factor that often influences material choice.

HDHMR: HDHMR is a great engineered wood product whose price aligns with its quality and durability. However, in the long run, it might be a more cost-effective choice due to its robustness and low maintenance needs.

Plywood: Plywood comes in various price points based on the type and grade chosen. Even while high-quality plywood can be costly, there are still less expensive options available that keep the same quality.

Conclusion

In the end, there are a number of variables that can be used to distinguish between HDHMR and plywood, including the possibility of germs, density, quality, consistency, and durability. However, the improved quality of Action Tesa HDHMR boards dispels the common idea that they are more resilient and long-lasting than plywood. For homeowners, architects, and interior designers, creating an affluent appearance is the first and last choice.